Automotive Camera MES

CanLab Manufacturing Engineering Services (MES) is a service that helps customers

Optimise the manufacturing process of products from development to mass production (small to large quantities).

This reduces and prevents manufacturing issues and helps customers realise their goals.

Automotive Camera MES (Manufacturing Engineering Service) Concept & Proposal

Canlab MES scope

- Manufacturing Process Planning

- Prototype Support

- Should-Cost Analysis

- Tool Design and Development

- Vendor Management

- Assembly & FIRST ARTICLE

INSPECTION Engineering - CALIBRATON Engineering

- EOL (END OF LINE) Engineering

Canlab MES Advantages and Competitiveness

-

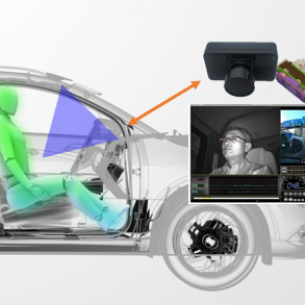

Front Camera

-

Rear Camera

-

Surround view

-

Driving video recorders

-

Monitoring driver status

-

Camera monitoring system

-

Side and rear cameras

-

Sensing camera

Automotive camera MES core processes and process-specific equipment

-

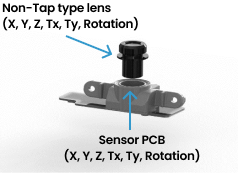

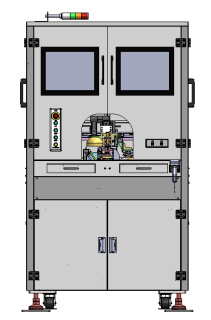

Active Alignment Type Automotive Camera Assembly & Test

Active Alignment Type Automotive Camera Assembly & Test

- Camera Assembly with Active Alignment (Lens & Image Sensor) Calibration

- Adhesive application and UV curing (welding)

- Camera assembly inspection

- MES integration of inspection results

-

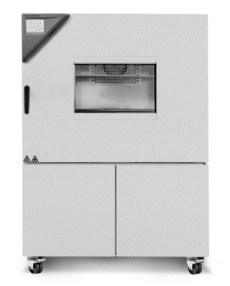

Heating Curing Equipment

Heating Curing Equipment

(Exclude critical process equipment)

-

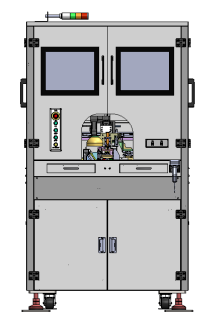

Active Alignment Type Automotive Camera Final Test After Heating Curing

Active Alignment Type Automotive Camera Final Test After Heating Curing

- Assembled camera position correction with active alignment (AA equipment condition matching)

- Camera after thermal curing (bonding) Assembly status inspection

- MES integration of inspection results

-

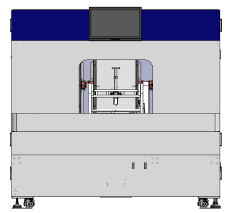

Automotive Camera Intrinsic Parameter Calibration

Automotive Camera Intrinsic Parameter Calibration

- Extracting camera internal parameters (focal length, main point, distortion factor)

- Saving internal parameters to EEPROM

- MES integration of inspection results

-

Automotive Camera EOL

Automotive Camera EOL

(End Of Line)

- Final Inspection (performance & image quality characteristics, etc.)

- MES integration of inspection results

Equipment retrofit scope by core process

| Process name | Action type | Equipment name | Modification range | Duration (Modification & Verfication) |

|---|---|---|---|---|

| Assembling and testing in-vehicle cameras | Semi- auto |

ActiveAlignment Type Automotive Camera Assembly & Test Equipment |

|

4~5 month |

| Automotive Camera Testing (after heat curing) | Semi- auto |

ActiveAlignment Type Automotive Camera Final Test Equipment After Heating Curing |

|

|

| Extracting and saving camera internal parameters | Semi- auto |

Automotive Camera IPC (Intrinsic Parameter Calibration) |

|

|

| EOL (End Of Line) | Semi- auto |

Automotive Camera EOL (End of Line) Equipment |

|

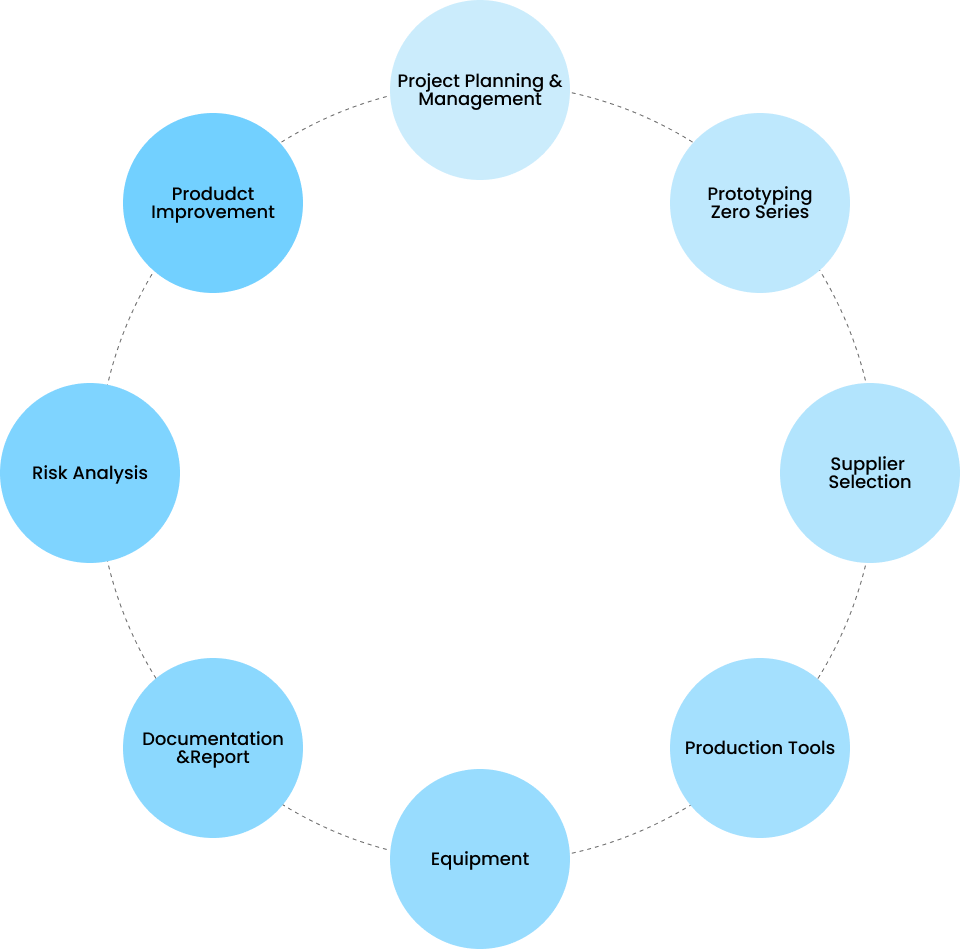

MES Processes

| MES Process | Discussion content | |

|---|---|---|

| Step 1 | MES scope consultation |

|

| Step 2 | Camera specification consultation |

|

| Step 3 | Process Specification Discussion |

|

| Step 4 | Equipment specification consultation |

|

| Step 5 | Price & Schedule Discussion |

|

| Step 6 | Contract Discussion |

|

| No | Item | Duration |

|---|---|---|

| 1 | Step 1 ~ Step 6 Consultation | 1~2 month |

| 2 | Camera Develop, Build, Validate | 3 month |

| 3 | Equipment modifications, validation | 4~5 month |

| 4 | Build reports | 1 month |

Total duration is subject to change based on MES process-specific arrangements

Lab-based in-car camera performance evaluation and analysis coverage

| Classification | No | Item | Standard / Chart or Equipment (Commercial) |

Criteria | Evaluation & Analysis Method Classification |

|---|---|---|---|---|---|

| Default Item | 1 | MTF (Modulation Transfer Function) | ISO 12233 / ISO 12233 Chart | Depends on Lens Spec & ISP Tune | Objective |

| 2 | Chromatic Aberration | ISO 12233 / ISO 12233 Chart | Depends on Lens Spec | Objective | |

| 3 | Shading | No Standard / Light Box | Depends on Lens Spec & ISP Tune | Objective | |

| 4 | WDR (Wide Dynamic Range) | No Standard / Imatest Chart | Depends on CIS Spec & ISP Tune | Objective | |

| 5 | OECF (Opto-Electronic Conversion Functions) | ISO 14524 / ISO 14524 Chart | Depends on CIS Spec & ISP Tune | Objective | |

| 6 | Noise (SNR : Signal to Noise Ratio) | ISO 15739 / ISO 15739 Chart | Depends on CIS Spec & ISP Tune | Objective | |

| 7 | Auto White Balance | No Standard / X-Rite ColorChecker | Depends on CIS Spec & ISP Tune (AWB On & Off Classification) | Objective | |

| 8 | Color Reproduction Accuracy | No Standard / X-Rite ColorChecker | Depends on CIS Spec & ISP Tune | Objective | |

| 9 | Total Y Value in Low Illumination Level | No Standard / X-Rite ColorChecker | Depends on CIS Spec & ISP Tune | Objective | |

| 10 | Bending | No Standard / 50Hz & 60Hz Light | Depends on ISP Tune | Subjective | |

| 11 | LFM (LED Flicker Mitigation) |

No Standard / LED Type Speed Limit Traffic Sign (PWM Control Included) |

Depends on ISP Tune | Subjective | |

| 12 | Flare (Veiling Glare) & Ghost | ISO 18844 / ISO18844Chart | Refer to ISO 18844 | Objective | |

| 13 | FrameRate |

No Standard / Image Engineering LED Panel |

Depends on CIS Spec | Objective | |

| Custom Item | 1 | Custom Item | - | - |